Material Composition

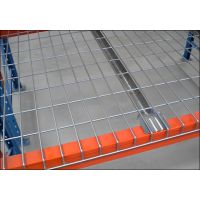

Made from galvanized steel, this mesh resists rust and corrosion, typically available in zinc coating weights ranging from G-60 to G-90 for enhanced durability.The “G” denotes galvanized, and the number indicates the weight of the zinc coating on the surface of the steel in ounces per square foot.

- G-60: This indicates a coating weight of 0.6 ounces of zinc per square foot of steel surface. It provides a standard level of corrosion protection and is commonly used for interior or less demanding applications.

- G-90: This specifies a heavier coating weight of 0.9 ounces of zinc per square foot of steel surface. With a thicker layer of zinc, G-90 offers a greater level of corrosion resistance, making it suitable for exterior applications or environments with higher exposure to moisture or corrosive elements.

Reinforced Plaster Wire Mesh Specifications

- Construction and Pattern: The mesh features steel wires welded at each intersection to form a rigid grid, with diamond mesh patterns commonly in sizes from 1/2 inch (12.7 mm) to 2 inches (50.8 mm), offering superior grip and mechanical keying for plaster applications.

- Gauge: Wire gauges range from 18-gauge (1.02 mm diameter) for lighter applications to 14-gauge (2.03 mm diameter) for more demanding structural support. The variation in gauge allows for customization to project-specific load requirements.

- Sheet and Roll Dimensions: Sheets are sold in sizes such as 27 inches (686 mm) by 96 inches (2438 mm), with roll options extending from widths of 24 inches (610 mm) to 48 inches (1219 mm) and lengths up to 200 feet (60960 mm).

- Mesh Size Range: Mesh openings are designed to range from 1/4 inch (6.35 mm) to 1 inch (25.4 mm), ensuring sufficient surface for plaster adhesion while allowing for proper embedment of plaster mix for robust finishes.

- Installation: Secure attachment is facilitated using nails or staples at intervals of 6 inches (152 mm) along the framing to prevent displacement that could lead to plaster cracking.

- Application: Its use spans from residential to commercial and industrial settings, suitable for both interior and exterior finishes, and particularly beneficial in architectural scenarios requiring a more resilient finish than drywall, including historical restorations or curved architectural features.