Materials

Our Wire Mesh Lockers are made from high-grade steel wire, ensuring durability. They are coated with zinc or epoxy to prevent rust. For specific applications, stainless steel options are available for moist environments. This ensures long-lasting, reliable storage solutions.

Manufacturing Process

Metech Welded Mesh Inc prioritizes quality at every manufacturing step, ensuring our Wire Mesh Lockers are secure and durable for all industries. The process starts with detailed planning and CAD software to design each locker for its specific purpose.

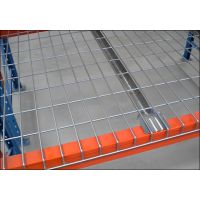

- Cutting and Shaping: The steel wire is cut to length and shaped according to the design specifications. This is typically done using automated machinery, which ensures precise dimensions and a consistent finish.

- Welding: The core of the manufacturing process involves welding the wire frames to form the locker’s structure. Advanced welding techniques are employed to ensure strong, seamless joints. The welds are then polished to remove any rough edges, ensuring a smooth finish.

- Coating: once the welding is complete, the lockers undergo a coating process. This may involve galvanization or the application of epoxy powder coating. This step not only enhances the aesthetic appeal of the lockers but also serves as a protective layer against corrosion and wear.

- Assembly: The final step involves assembling the locker components. This includes fitting doors, locks, and any additional features specified in the design. The assembly process is carried out with precision, ensuring that the final product is robust and functional.

- Quality Control: Before leaving the factory, each locker is subjected to rigorous quality control checks. This ensures that the product meets our high standards of strength, durability, and functionality.