=== The following information is translated by computer. Please contact the publisher.= = =R1800—SHyper dispersant

R1800—SUltra-dispersant is a special kind of polymer-type multi-functional wetting coating dispersant, which is produced under high temperature and high pressure with precise ratio of coating agent and dispersant. Its molecular structure can be divided into two parts. One part is anchoring group, the other part is solvation chain. Its main function is to form a certain thickness of protective coating (coating) on the surface of pigments and various powders. When the pigments and powders adsorbed with Hyperdispersant are close to each other, it is difficult for the pigments and powders to form compact aggregates or flocculants due to the space barrier of the protective layer (envelope), which makes the pigments and powders disperse easily and have good dispersion stability in the medium. Its dispersing effect is far superior to others.BykBYK-W 996。

R1800—SThere are two different ways of action of hyperdispersant, that is, in the process of treating the surface of pigments and powders, and in the process of dispersing pigments and powders.

In the process of surface treatment of pigments and powders, the action mechanism is: in the synthesis of organic or inorganic pigments and powders, once the particles of pigments and powders are formed (primary particles), they are specially designed.R1800—SHyperdispersant can quickly adsorb to the surface of pigments and powders to form a protective layer (coating), surround the pigments and powders, and fill the lattice defects of the pigments and powders, so as to purify the active points on the surface of pigments and powders which are easy to agglomerate, so as to effectively prevent further agglomeration of pigments and powders, even if the lattice defects of the pigments and powders are filled. Pigments and powder particles coagulate during filtration, compaction and drying.R1800—SThe isolation effect of Hyperdispersant and the coagulation state of pigments and powders are also very loose (the contact between particles is mainly point and edge). The obtained pigments and powders are particularly easy to disperse in the subsequent application process.

The mechanism of action in the dispersing process of pigments and powders is as follows:R1800—SThe anchoring group of Hyperdispersant is adsorbed on the surface of pigments and powders, while the solvation chain can be dissolved in the dispersing medium rapidly and has good compatibility with the dispersing medium.R1800—SHyperdispersant can greatly reduce the interfacial tension between the pigment and powder particles and the dispersing medium, so that the pigment and powder can be quickly wetted by the medium in the dispersing process. At the same time, because of the space barrier of the protective layer, when the pigments and powders adsorbed with surface treatment agent are close to each other, it is difficult for the pigments and powders to further converge, which makes the pigments and powders disperse easily and have good dispersion stability in the medium.

R1800—SUsage effect of Hyperdispersant

R1800—SThe greatest characteristic of Hyperdispersant is that it weakens the interaction between pigment and powder particles in dispersing medium, and increases the wettability and dispersion stability of pigment and powder in dispersing medium. It not only provides a unique new process for the preparation of dispersion system, but also has obvious technical and economic benefits. Its advantages are shown as follows.

Application in Masterbatch, Paint and Plastic ProcessingR1800—SType D dispersant has the following advantages.

(1) Reducing Pigment CostIt can improve the dyeing strength of organic pigments.25%At the same time, the covering power of inorganic pigments is improved. Even if the amount of pigments is reduced10% to 20%And it will not weaken the colouring effect, so as to achieve the purpose of saving raw material costs.

(2) Improving Production EfficiencyWhile the traditional formula increases the screw speed, the production efficiency is improved, but the dispersion effect of the color is often reduced, and the traditional formula is used.R1800—SAfter the hyperdispersant, the output per unit time can be increased, and the dispersion effect will not be reduced, sometimes even greatly improved.

(3) Improving product qualityEliminate spot and middot, stain and shrinkage, improve surface condition, improve product smoothness, eliminate surface defects, improve impact strength, improve brightness and brightness.

(4) Reducing Processing CostGood product quality and stability, and ldquo; furnace and rdquo; low rate, less waste, saving production costs.

(5) Improving Processing ConditionsReduction of pigments and powders and ldquo; crowding and rdquo; degree and pigment dust during pre-mixing. Reduce waste of pigments and powders. Save the cost of raw materials.

(6) Having inertiaIt does not interact with other additives. Proper use will not affect the original properties of the resin (melting index)`Viscosity and middot; Melting point/Softening point and stress/Strain and hardness/Softness, light resistance, impact resistance, itching resistance, aging resistance, low temperature flexibility) have side effects.

(7) It has resistance to insulation and adds 1,000 parts to kaolin treatment.2It can improve the insulation performance.

R1800—SDosage of Hyperdispersant

Addition amount was determined according to oil absorption value and particle size of different powders. Refer to the table below to add:

Product Name | Mesh number | Dosage | Mesh number | Dosage | Mesh number | Dosage | Mesh number | Dosage |

Calcium carbonate | 800 | 0.2% | 1250 | 0.3% | 1500 | 0.35% | 3000 | 0.5% |

Talc | 800 | 0.32% | 1250 | 0.38% | 1500 | 0.47% | 3000 | 1% |

kaolin | 800 | 0.3% | 1250 | 0.35% | 1500 | 0.45% | 3000 | 0.8% |

Pigment | Such as: carbon black, titanium dioxide, group blue, chrome yellow and so on, about the amount of additions in the0.3-1.2%Adjust according to the actual formula. | |||||||

R1800—SMain Functions of Hyperdispersants R1800—SThe main functions are dispersed wrapping, lubrication demoulding, toughening and brightening, can be used as smooth opener, can replace maleic anhydride grafting, can adjust product flow rate, can improve product impact strength and tensile strength and so on. | ||||||||

R1800—SIdentification methods

Identification of physical properties

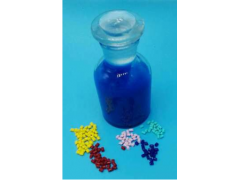

- R1800—SThe Hyperdispersant is a blue paste liquid.

- Take a small amountR1800—SThe superdispersant is added with clear water.R1800—SDispersants will quickly dissolve in water and produce white flakes and a small amount of foam. (Principle: Dispersant can disperse immediately when it meets water, so it can be compatible with water very quickly; if used in powder, it can quickly disperse and wet. White flake is the coating agent, which plays the role of powder pigment coating. Foam is caused by rapid molecular motion dispersed in water, as shown in powder.R1800—SIt can disperse quickly.

- This is the only blue paste dispersant on the market at present, and the only product that synthesizes dispersant and coating agent on the market at present. (Benefits of Blue Phase.1.Used in white products can play a whitening and better visual sense.2.Used in black products can play a blackening effect and brightness.Three.It can be used in red products to increase red color.4.Used in yellow products can play a role in fixing the color.)

- R1800—SHyperdispersant is the only oil dispersant that can dissolve in water.。

Two.Disabled Items

- R1800—SHyperdispersants are prohibited from being used in cold-treated powders. (It means that the product can not be used without warming up, because it can not be fully utilized.R1800—SDispersion coating effect of Hyperdispersant

- R1800—SHyperdispersants are prohibited from being used in waterborne coatings and water-based inks.

R1800—SExamples of Usage of Hyperdispersant in Masterbatch

I.Calcium carbonate or talc powder filler for blow moulding. Some companies produce calcium carbonate or talc powder blow-moulding grade fillers when used in blow-moulding appear small granular pits. Such phenomena are caused by three factors.1.Calcium carbonate source contains high purity silicon dioxide. Silicon dioxide can not be refined when grinding, so blower mesh will be blocked with lump of non-melting garbage, the same product will also appear numb ideas.2.This phenomenon can also be caused by inadequate fineness of calcium carbonate (too low a number of items).Three.Because the powders are too fine, the finer the powders are, the easier they are to agglomerate together. If there is no good dispersant to disperse the powders, the same problem will arise.

Some companies reflect how the active calcium carbonate I bought can also have this phenomenon. In fact, it is very simple. Usually, the active method of powder treatment factory is to treat it with stearic acid or polyethylene wax. When treated, the powder was wrapped without dispersing at all. (Because stearic acid and polyethylene wax have no dispersibility at all, so-called dispersion is to encapsulate the powder to achieve the purpose of not easy agglomeration.) Because some manufacturers add additives in order to consider the cost problem, they can not achieve the purpose of encapsulation at all, and add time to accumulate too long and re-agglomerate at the same time. Together; so there will be netting numbness phenomenon.

If usedR1800—SWe can completely solve the third problem of poor dispersion of packages. becauseR1800—SHyperdispersant itself is synthesized by Hyperdispersant and coating agent under high temperature and pressure. Its product is blue paste, non-toxic and tasteless, and can be used as food contact grade. Its functional principle is that80Temperature conditions above degree CR1800—SIt can quickly wet into the powder to achieve dispersion, coating effect, after cooling, the coating agent will solidify. Therefore, the coated powders will no longer coagulate together, which fundamentally solves the problem.

2. Why is there a colour spot when coating the colour film? The main reason is the poor dispersion of masterbatch pigments and the caking phenomenon. For this reason, the color of the coating film is uneven, and there are even black spots caused by dispersion. It is advisable to purchase excellent dispersants (e.g. dispersants) in the production of masterbatches.R1800—SSuper dispersant; Correct control of processing temperature, and cleaning screw and machine head to solve this problem.

3. Why does the coated film produce mapped patches of varying shades (patterns)?How to solve it? The above phenomena are mainly caused by poor dispersion of masterbatches or fading of pigments in masterbatches due to poor temperature and heat resistance. It is also possible that the melt index of masterbatches differs greatly from that of coated resins, resulting in inconsistency in fluidity. Solution: Choose a good dispersant when making masterbatch (e.g.R1800—SSuper dispersant) Choose high temperature resistant pigments, and choose the carrier resin of color masterbatch to be similar to the melt index of the coating resin, and then adjust the temperature of each section of the coating machine properly to make the two resins have similar viscosities.

4. Why do some color masterbatches affect the thermal sealing properties of films? When the thermal sealing performance of the film without color masterbatch is normal, it is mostly related to additives in color masterbatch. At present, some low molecular weight polyethylene wax manufacturers use the method of adding paraffin wax in order to reduce costs and win customers.10% - 40%Unequal. The low molecular weight, low melting point and decomposition temperature of paraffin wax are far lower than those of low molecular weight polyethylene wax, which results in the decomposition and sublimation of paraffin wax during processing, migration to the surface of film and frosting phenomenon, affecting sealing fastness. Secondly, with the thermal decomposition of paraffins at different processing temperatures, small molecules will migrate to the surface and affect the heat sealing performance. The main role of low molecular weight polyethylene wax in color masterbatch is dispersive lubrication, if used.R1800—SUltra-dispersant can greatly reduce the use of low molecular weight polyethylene, thus achieving the goal.

5. What causes filament breakage in flat wire production? takeHigh Density PolyethyleneorpolypropyleneResin melt extruded flat film is cut into a certain width filament (called embryo filament) through a tool holder with a certain gap. The filament obtained by unidirectional stretching is called membrane split fiber in the world, and it is generally called flat filament in China. Flat silk can be woven into knitting bags on circular looms, and colored strips and tarpaulins can be woven on flat looms.

扁丝生产过程中的断头是在拉丝过程中经常出现的问题,断头会产生大量的废丝,使原料消耗大增,严重时造成停机,其产生的主要原因除了因树脂的熔体指数太大或拉伸强度不够,拉伸倍率太高、冷却水温太低,而结晶过快以及原料有杂质外,色母的分散不良,或因色母颗粒中颜料颗粒太大,以及载体与树脂相容性不好造成膜片表面不光滑。在挤出冷却水中带水过多造成拉伸温度偏低,往往在烘箱外断裂。如果是这种现象在生产色母粒时就选用好的分散剂R1800—S超分散剂可以彻底解决这一问题。

六.什么原因造成色母粒表面不光亮?色母粒的表面光滑程度可以初步判定色母粒的质量好坏。有些色母粒由于原料、配方、加工工艺等原因造成色母粒混炼分散不均匀,并造成色母粒表面毛糙。特别严重时,色母粒表面会有严重分散不良的色点。

色母粒在生产过程中发现表面不光洁,首先检验挤出温度是否适当。挤出温度或机头温度过高或过低都会引起表面毛糙,这时需调整挤出温度。如经反复调整后无效,则可能是由于下述原因造成。

- 颜料的分散性是否好,如果颜料的分子太硬,将会在塑料中分散不良,造成表面不光滑。

- 分散剂(低分子量聚乙烯蜡)质量是否合格、用量是否恰当。如有的低分子量聚乙烯蜡掺入石蜡,或为高密度低分子量聚乙烯蜡,都会影响颜料的分散性。

- 颜料的润滑性处理不恰当,无论采用什么样的手段,都无法得到一个分散性良好、表面光滑的色母粒产品。

所以希望使用R1800—S超分散剂、从根本上解决这类问题。

七.生产PVC塑料稳定剂(铅盐复合稳定剂、铅钡复合温度剂、钡锌复合稳定剂等等)加入0.5% R1800—S超分散剂可使复合稳定剂更好的与PVC相容、更均匀的分散在PVC里、并且起到内外润滑脱模作用、可大大的提高产品热稳定效果。

八、处理煅烧高岭土时加入R1800—S超分散剂可使高岭土分散效果提高、还可提高高岭土用在电缆料里面的绝缘性能。

contact supplier or email to admin@b2bgood.com for purchase help

PassAuthentication

PassAuthentication