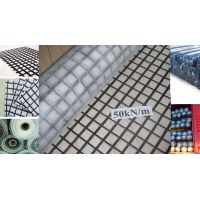

Fiberglass Geo Grid Net Fabric is a kind of earthwork base engineering material to strength the road surface and road bed.

The coated fiberglass mesh geogrids possess the advantage of high tensile strength in the warp and weft directions, low elongation, excellent temperature range, and good anti-aging and alkali-resistance. Above features enable glass fiber geogrid an ideal construction materials in asphalt pavement, concrete pavement and roadbeds. In addition, we also supply plastic or PP geogrids.

We supply mainly following types: composite geogrid geotextile fabrics; goegrid bonded geotextile; warp knitted geo grid and PP geogrid.

Fiberglass Geogrid Composite Geotextile Fabric Providing Improved Loading Capacity of Road Construction

Composite Geogrids are used for stabilize soils where a both reinforcing and separation between a granular base and very fine soil is required. The geocomposite binds closely to the soil being reinforced, separates different soil types and provides an effective filter action.

Composite geogrids are made by bonding a nonwoven geotextile to fiberglass geogrid. The polypropylene / polyester geotextile stitch bonding or paste on the fiberglass geogrid. With high tensile strength and excellent anti-tearing and anti-bursting performance, this new compound building materials are widely used in water conservation, road construction,architecture, subway and tunnels construction.

Typical Structures of Compound Fiber Glass Materials:

For fiberglass geogrid composite geotextile materials, geogrid used has a tensile strength of 20KN to 400KN.

Mesh size: 12.7x12.7mm, 25.4x25.4mm, 50x50mm

Elongation: <=4% or 3%.

Geotextile:

Non woven PET or pp geotextile

Unit weight: 25g/m2 to 500g/m2.

Fiber Grid convenient for construction, with less cost, to prevent road surface from subsiding and cracking and to provide stability for slopes and avoid the losing of the water and soil.

Fiber Geogrid Bonded Geotextile can prevent the reflection cracking, water damage, improve loading capacity, proling life time of pavement, in the project of road construction and renovation.

Technical Parameter

| Fiberglass Geogrid Bonded Non Woven Geotextile Composite Sheet Technological Standard | ||||||||||

| Specification | 30×30 | 50×50 | 60×60 | 80×80 | 100×100 | 120×120 | 150×150 | 200×200 | 300×300 | |

| Fiberglass geogrid properties (GB/T 21825-2008) | ||||||||||

| Mesh center distance(mm) | MD | 12.7±3.8 25.4±3.8 50.8±3.8 | ||||||||

| TD | 12.7±3.8 25.4±3.8 50.8±3.8 | |||||||||

| Breaking strength(kn/m) | MD | 30 | 50 | 60 | 80 | 100 | 120 | 150 | 200 | 300 |

| TD | 30 | 50 | 60 | 80 | 100 | 120 | 150 | 200 | 300 | |

| Breaking Elongation(%) | MD | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| TD | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | |

| Normal composite Geotextile properties (GB/T17638-1998) | ||||||||||

| Unit weight(g/m2) | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | |

| Breaking strength(kn/m) | 2.5 | 4.5 | 6.5 | 8 | 9.5 | 11 | 12.5 | 14 | 16 | |

| CBR mullen burst strength | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | |

| Tear strength | 0.08 | 0.12 | 0.16 | 0.2 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | |

| Sheet Width(m) | 1m-6m | 1m-6m | 1m-6m | 1m-6m | 1m-6m | 1m-6m | 1m-6m | 1m-6m | 1m-6m | |

Fiber Glass Warp Knitted Geogrid

Fiber glass geogrid is made with non-alkali fiberglass yarn through warp knitting. The warp knitting structure can make full use of the fabric yarn strength and improve the mechanical properties of the fiberglass mesh grids. Knitted fiberglass mesh grid enjoys good tensile strength, tearing strength to be used for modified asphalt. The key highlight is composite performance of asphalt mixture. With this geogrid as base material, the roadbedding significantly improves substrate wearability and shearing ability.

Application

(1)Roadbed reinforcement of road and railway, crack prevention, increasing of roadbed strength;

(2)Reinforcement and stabilization of riverside,embankment and side slope;

(3)Dyke reinforcement on soft ground for stress evenness, sedimentation adjustment, increasing of stability and loading capacity of fundus;

(4)Reinforcement of the surface of road and bridge.

Compared to traditional materials, fiberglass geogrid can reduce construction cost, extend road service life, and prevent reflective crack in highway projects.

Alkali Resistant Fiberglass Geogrid For Construction: Used in reinforcing of soft soils and road root for railways, airports, water conservancy, dams construction projects.

High Tensile Polyester Fiber Glass Geogrids / Textiles Used in the enhancement of cement and concrete pavement of road.

Fiberglass Geogrid Technical Data:

|

Product specifications and performance parameters (geogrids of ordinary glass fiber type)

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Also Supply: Plastic net biaxial geogrids made of polypropylene:

Plastic Biaxial Geogridis are applied in highway, railway, slope protecting projects to improve bearing capacity of road founation and prolong the service life.

Features:

1.Wth high tensile strength in longitudinal and transverse directions.

2.Provide an chain system of more effective force bearing and spreading for the soil.

Application:

PP Biaxial Geogrid Fabric is used as reinforcement netting fabric for permanent load-carrying foundations of large areas.

Specifications

| Specification Item | PPG15-15 | PPG20-20 | PPG30-30 | PPG40-40 | PPG45-45 |

| Longitudinal Tensile Strength ≥(KN/m) | 15 | 20 | 30 | 40 | 45 |

| Transverse Tensile Strength≥(KN/m) | 15 | 20 | 30 | 40 | 45 |

| Longitudinal Elongation≤(%) | 15 | ||||

| Transverse Elongation≤(%) | 13 | ||||

| Longitudinal Strength at 2% Strain ≥(KN/m) | 5 | 7 | 10.5 | 14 | 16 |

| Transverse Strength at 2% Strain ≥(KN/m) | 5 | 7 | 10.5 | 14 | 16 |

| Longitudinal Strength at 5% Strain ≥(KN/m) | 7 | 14 | 21 | 28 | 32 |

| Transverse Strength at 5% Strain ≥(KN/m) | 7 | 14 | 21 | 28 | 32 |

| Remark | Roll Length:50m Roll width:1~4m | ||||