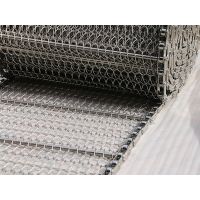

Проволочный конвейер представляет собой многофункциональную транспортную систему, изготовленную из соединенной проволоки, которая образует прочную и открытую сетку. Эти конвейеры предназначены для облегчения перевозки и обработки грузов в различных промышленных условиях. Из - за своей металлической структуры они особенно подходят для среды, требующей долговечности, термостойкости или воздействия суровых химических веществ.

Материалы

- Нержавеющая сталь: идеально подходит для жарких, влажных или грязных мест. Нержавеющая защита.

- Углеродная сталь: очень прочная, подходит для сложных задач, но если не быть осторожным, может ржаветь.

- оцинкованная сталь: похожа на углеродистую сталь, но имеет защиту от ржавчины. Эффективность с точки зрения затрат.

- Высокоуглеродная сталь: более прочная, чем обычная сталь, подходит для требовательных работ.

- Никель сплав: очень долговечный, очень термостойкий, не ржавеющий.

Спецификация

- Размер и производительность

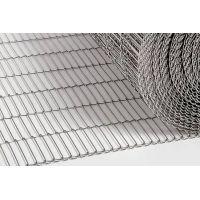

Доступная ширина: от 200 до 5000 мм, ширина до 160 дюймов может быть выбрана для большего спроса.

Скорость: до 1000 футов в минуту.

Температура: до 2100 & deg; F, это зависит от материала ленты. - Долговечность

Край: Укрепляется краем сустава пальца, чтобы продлить время износа. - Подробные чертежи нитей и стержней

Диаметр линии: диапазон от 1,2 мм до 3 мм.

Диаметр креста: от 1,2 мм до 4,0 мм для увеличения прочности.

Размер плоской линии: от 1,0 мм×0,7 мм и 6,0 мм×3.0 мм для удовлетворения различных контактных потребностей.

Расстояние между спиральными линиями: Selec & # 116; Ионы от 4 до 22 мм регулируют плотность сетки.

Расстояние между поперечными стержнями: широкий диапазон от 4 мм до 33 мм, имеет много приращений, таких как 5, 6, 8, 10 и т. Д. Для конкретного применения.

Диаметр спирали: от 0,9 мм до 3,0 мм для обработки различных нагрузок.