Using Method:

1. The paving surface for geogrids should be relatively flat. After the paving layer is accepted, longitudinal skewing should be prevented by first drawing a white line or hanging line according to the width of the geogrids in the paving layer, then beginning with paving. U-shaped nails should then be used to fix the end of the grating (4 nails per meter wide, with uniform distance).

2. After fixing the end of the geogrids, a laying machine or manual method should be used to slowly pull the grille forward to lay. Every 10 meters should be manually inspected and straightened once until a full section of the grille is finished before laying the next section; this process should be repeated.

3. Successive paving: Geogrid roll length should be used as a unit for paving section length. After paving a section of geogrids or river bank section, an overall inspection of the quality of paving should be conducted before proceeding to paving the next section.

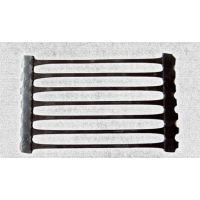

Uniaxial PET Geogrid with HDPE Coating

We provide polyester geo-grid as primary reinforcement with HDPE coating for a design life of 120 years at 30°C. Geogrid Uniaxial PET with low density polyethylene sheath and ultimate tensile strength of 200kN/m. It offers ultimate tensile strength for reinforcement in flexible retaining wall etc.

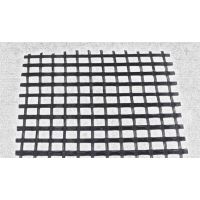

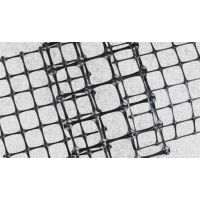

Polyester Biaxial Geogrids

Polyester biaxial geogrids are characterized by high tensile strength, small fracture elongation, and a low creep coefficient. The temperature resistance range is -70 degrees Celsius to 180 degrees Celsius, and the geogrid is also resistant to UV radiation and microbial corrosion. The width can reach up to 6m, resulting in high tensile strength at low strain capacity. Longitudinal and transverse ribs work together to fully utilize the geogrid's embedded locking effect on the soil body. During production, the polyester geogrid is pressed with a rough pattern to enhance the roughness of the surface and improve the friction coefficient between the geogrid and the synthetic soil body. Polyester geogrids are not eroded by acid, alkali, salt solutions, and oil at room temperature, do not dissolve in water or succumb to microbial attack, and can withstand UV light and oxygen erosion. Furthermore, the junction will not crack or break due to the synergistic force of the longitudinal and transverse ribs. In actual engineering, after compaction of the filler, it meets permanent engineering construction needs.