отправка товара :3 В течение дня

посылать запрос

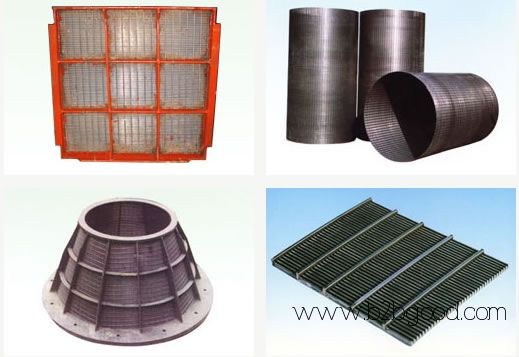

Mine Screening Mesh: This robust and wear-resistant mesh plays a crucial role in mining operations. It's used to separate mined materials by size, allowing for efficient processing and sorting of valuable minerals. Compared to regular woven mesh, mine screening mesh utilizes thicker wires and reinforced structures to withstand heavy loads and harsh mining environments. It can be customized with specific hole sizes depending on the minerals being processed.

Mine Screening Mesh,Stainless Steel Bonded Screen Mesh,Vibrating Screen Mesh

Wetter Stainless Steel Wire Mesh Factory is renowned for its comprehensive portfolio of Mine Screening Mesh products, designed to meet the robust demands of the mining industry. Our diverse selection is tailored to optimize screening processes across various mining applications, ensuring efficient material separation and durability in challenging conditions.

Mesh Types

- Stainless Steel Bonded Screen Mesh: Ideal for rigorous mining operations, this mesh type offers superior durability and resistance to wear, extending the operational life of screening systems.

- Strip Sheet Mesh: Designed for precise material separation, our strip sheet mesh provides uniform openings that guarantee consistent performance in fine screening applications.

- Screen Basket: Custom-built to integrate into existing screening setups, our screen baskets enhance the efficiency and reliability of material processing.

- Vibrating Screen Mesh: Engineered to endure the dynamic forces of vibrating screening equipment, this mesh type maintains integrity and performance under extreme conditions.

- Cylinder Type Screen Mesh: Optimized for rotary screening applications, this cylindrical mesh facilitates effective material processing and separation.

- Arc Special Screen Mesh: Tailored to unique screening requirements, our arc-shaped mesh addresses specialized process needs in various industries.

- High Strength Screening Mesh: Developed for heavy-duty applications, this mesh withstands harsh operational environments, minimizing the risk of breakage and maintenance requirements.

Applications

- Coal Processing: Efficiently separates and cleans coal, enhancing the quality and purity of the final product.

- Mineral Extraction: Supports the extraction and separation of minerals, contributing to more refined and efficient processing.

- Petroleum Industry: Used in the petroleum industry for material filtration and separation processes.

- Chemical Industry: Facilitates the screening and classification of chemicals, ensuring product consistency and quality.

- Grain Industry: Improves grain processing by enabling effective cleaning, sorting, and separation.