brand:WINNER

Model:WCW

Voltage:380V

Capacity:100-800T/H

Set up:1Set

supply:100Set

Deliver goods:30 days after paydown

Construction demolition waste sorting equipment /construction waste recycling machine can achieve the construction waste disposal. After the screening of the construction waste through a specific iron removal equipment to remove the iron material contained in the coarse and medium crushing, fine crushing equipment and processing, processed into a certain size of the recycled aggregate, and finally applied to the road stone Burning brick, cement blends and so on.

Applications of Construction demolition waste sorting equipment /construction waste recycling machine:

Crushing and screening for concrete fragments, asphalt pieces, bricks, stones, wood, plastic, gypsum and mortar, steel and nonmetallic.

Input products: the mixture of construction waste,which is composed of road concrete blocks, asphalt concrete blocks, old building blocks, building site waste, etc.

Output products: Iron, steel, impurities, plastic and different sizes of stones and bricks. All sieving materials are finally used for roadbed stone, unburned bricks, cement admixtures and so on.

Capacity: 100 tons per hour to 800 tons per hour.

Technical parameters table of Construction demolition waste sorting equipment /construction waste recycling machine:

|

Model |

WCW-100 |

WCW-150 |

WCW-200 |

WCW-300 |

WCW-400 |

WCW-500 |

WCW-800 |

|

Feeding Size |

<=500mm |

<=600mm |

<=600mm |

<=750mm |

<=750mm |

<=600mm |

<=900mm |

|

Capacity T/h |

100 |

150 |

200 |

300 |

400 |

500 |

800 |

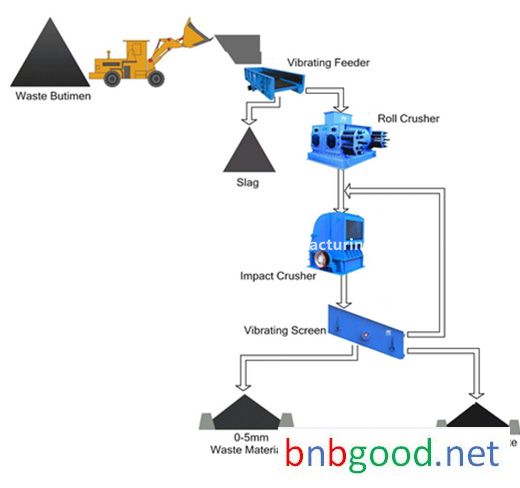

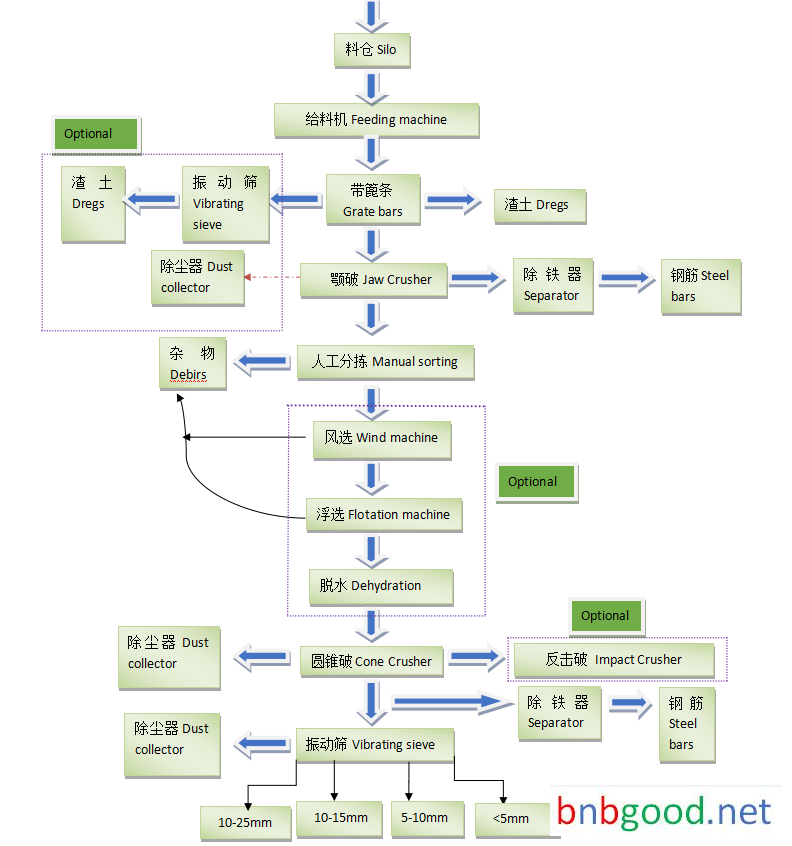

Machine pictures and processing chart of Construction demolition waste sorting equipment /construction waste recycling machine:

The raw material of the construction waste is crushed through the feeder into the crusher, and the material after the crushing is sent by the belt (the iron is transported at the same time as the belt conveyor). The sieving station is sieved through the screening station. Four materials are 0-5mm, 5-10mm, 10-15mm,>15mm(According to customer needs can change),Which 10-15mm, >15mm material in the material before the light material handling,> 31.5mm of the material from the new break into the closed loop.

1.Economic value

(1)Brick, stone, concrete and other waste materials after crushing, can replace sand, used in masonry mortar, plastering mortar, concrete cushion. Waste concrete block material after pulverization can cooperate with standard sand as fine aggregate mortar mix for the wall surface plastering, roof screed, masonry mortar, floor brick making etc.

(2)The aggregate used in the construction of the waste bricks after being crushed. Making the partition board, not only the light intensity is high and the sound insulation, the expansion coefficient is small, because the material is easy and cheap, but greatly reduces the cost of the plate.

(3)The waste concrete block material after crushing to cast-in-place concrete or prefabricated in aggregate used for building non load bearing parts. This will not only save the construction funds, and will not reduce the strength of the building.

2.Environmental value

Comprehensive utilization of construction waste not only achieved certain economic benefits, and improve the environment, beautify the city, largely to avoid the construction waste disposal, the release of harmful gases to city residents health hazards.

contact supplier or email to admin@b2bgood.com for purchase help