brand:Unique New Material

Set up:2000meter

supply:200000000meter

Deliver goods:10 days after paydown

Purchase immediately

===under info was translated buy computer===

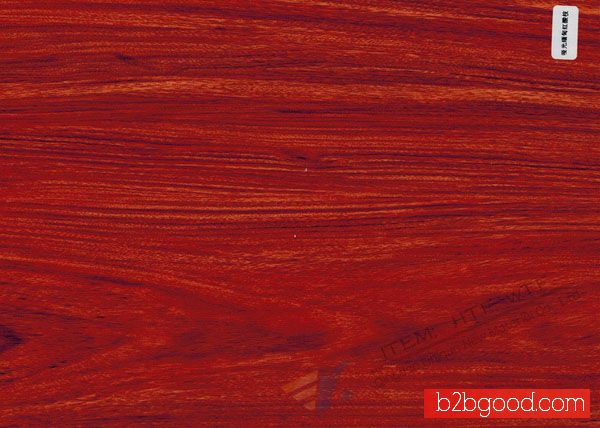

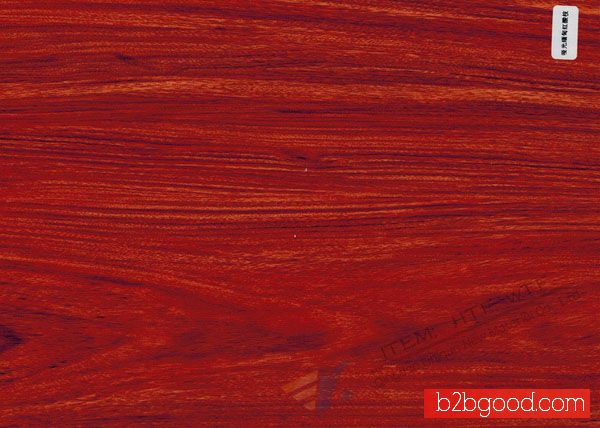

Wood grain transfer foil,WPC transfer foil, floor transfer foil, skirting transfer foil, photoframe transfer foil, door frame transfer foil, wallboard transfer foil, MDF transfer foil, PVC panel transfer foil, transfer foil on the glass, marble foil, WPC wall panel Heat transfer film

Characteristics of Wood grain transfer foil, transfer the wood grain pattern onto the workpiece surface by heat transfer. Not easy to fade, realistic wood pattern, improve product grade.

Wood grain transfer foil is widely used for: aluminum alloy doors and windows, anti-theft door, fire-proof door, steel wood furniture, filing cabinets, computer cover, household appliances, metal accessories which resistant to high temperature.

Wood grain transfer foil process is, through the disposable heating for transfer foil, transfer the decoration pattern on wood grain foil onto the surface of decorative construction material, to form high quality decoration skin. During the heat transfer process, separate the protection layer and pattern layer from PVC base under the combined function of heating and pressure, the hot melt adhesive glues the decoration layer and base material together forever.

The Wood grain transfer foil is made of polyethylene foil which printed with wood grain decorative layer. The surface is coated with protective layer, base color layer, decoating layer and hot melt adhesive layer. Through heating silicon roller by high temperature, impose temperature and pressure on transfer foil, to separate the transfer layer composed of wood grain layer, surface protection layer and base color layer from polyethylene, after the Wood grain transfer foil is transferred onto the surface of artificial board or furniture parts, the decorative pattern on the surface has formed, then the surface has excellent performance like abrasion resistance, heat resistance and light resistance, with novel and beautiful patterns, stable color, widely used as decorative materials. Because of the characteristics of its corrosion resistance, impact resistance, aging resistance, wear-resistant, fire proof, keep color for long service life in outdoor use, many commodities adopt this method to make wood grain.

Normal specifications for Wood grain transfer foil: thickness: 19-23microns, width can be produced according to order, length: 500m/1000m per roll, color: wood grain, gold, silver, brushed, wood thorns, marble, white marble, antique and many other patterns, can also develop new color and patterns according to market demand. The Wood grain transfer foil l minimum quantity: 2000m.

contact supplier or email to admin@b2bgood.com for purchase help

Wood grain transfer foil,WPC transfer foil, floor transfer foil, skirting transfer foil, photoframe transfer foil, door frame transfer foil, wallboard transfer foil, MDF transfer foil, PVC panel transfer foil, transfer foil on the glass, marble foil, WPC wall panel Heat transfer film

Characteristics of Wood grain transfer foil, transfer the wood grain pattern onto the workpiece surface by heat transfer. Not easy to fade, realistic wood pattern, improve product grade.

Wood grain transfer foil is widely used for: aluminum alloy doors and windows, anti-theft door, fire-proof door, steel wood furniture, filing cabinets, computer cover, household appliances, metal accessories which resistant to high temperature.

Wood grain transfer foil process is, through the disposable heating for transfer foil, transfer the decoration pattern on wood grain foil onto the surface of decorative construction material, to form high quality decoration skin. During the heat transfer process, separate the protection layer and pattern layer from PVC base under the combined function of heating and pressure, the hot melt adhesive glues the decoration layer and base material together forever.

The Wood grain transfer foil is made of polyethylene foil which printed with wood grain decorative layer. The surface is coated with protective layer, base color layer, decoating layer and hot melt adhesive layer. Through heating silicon roller by high temperature, impose temperature and pressure on transfer foil, to separate the transfer layer composed of wood grain layer, surface protection layer and base color layer from polyethylene, after the Wood grain transfer foil is transferred onto the surface of artificial board or furniture parts, the decorative pattern on the surface has formed, then the surface has excellent performance like abrasion resistance, heat resistance and light resistance, with novel and beautiful patterns, stable color, widely used as decorative materials. Because of the characteristics of its corrosion resistance, impact resistance, aging resistance, wear-resistant, fire proof, keep color for long service life in outdoor use, many commodities adopt this method to make wood grain.

Normal specifications for Wood grain transfer foil: thickness: 19-23microns, width can be produced according to order, length: 500m/1000m per roll, color: wood grain, gold, silver, brushed, wood thorns, marble, white marble, antique and many other patterns, can also develop new color and patterns according to market demand. The Wood grain transfer foil l minimum quantity: 2000m.

contact supplier or email to admin@b2bgood.com for purchase help