العلامات التجارية:Huaway Guardrail Engineering Co.

تسليم:3في غضون أيام

Road Safety Guardrail Barrier System - Beam Type Guard Rails, Post, Delineators,Tiling, Kerbs & Concrete Barriers

Road safety guardrail barriers are widely used for highway road and bridge safety and fixed on the side of the roads especially on curves and slopes for preventing vehicles from riding out from roads. Road safety guardrail is also known as traffic safety barriers.

Features of Road Safety Guardrail Barrier:

-The systems ensure minimum damage to the vehicle and its occupants

- During collision, the beam absorbs maximum energy by flattening out laterally and restrains the vehicle from veering over.

- Prevents the vehicle from skidding back onto the carriage way by controlling exit angles through gradual deceleration and effective redirection of the vehicle back on to the road.

- Enables quick repairs in case of accidents.

- All components are galvanized for longer life.

Application

- To provide railing protection to motor vehicles at dangerous road areas such as steep slopes, high embankments, obscure curves/bends, sharp corners.

- To absorb sudden impact during collision thus minimizing injury to vehicle and passenger.

- To act as a directional railing for vehicles moving in the right direction.

- To act as a median barrier for avoiding head on collision.

- To act as a protective barrier for pedestrians along the highway.

-Normal Specification: 4320*310*83*3mm, available in different sizes

-Profile: w-beam; thrie-beam

-Standards: JT/T 281-1995, AASHTO M-180, RAL-RG620, SPS98S, any other International Standards.

-base steel: Steel Grade Q235B (equivalent to S235JR / DIN EN10025 and Gr.D / ASTM A283M)

-The thickness of the steel: 3mm, 4mm, 6mm, or custom sizes

-Finish: Hot dip galvanized or PVC coating.

-The thickness of galvanizing: 70um, or customized

Guard Rail for Road Safety Barrier System - Project Illustration with Materials and Construction

1)Guardrail and delineators

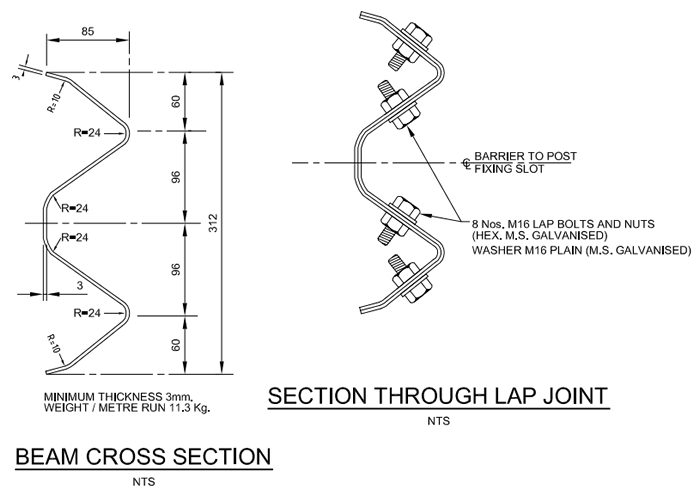

Beam Type Guard Rail: 3mm Min., weight / metre run 11.3kg

Heavy Duty Cat's Eyes / Reflectors

Tensioned Wire Rope Barrier

Crash Cushions

End Terminals

Median Gate barriers

Overheight warning systems

2)Tiling

Interlocking Tiles any shape, pattern, colour(6cm thick) m2

Interlocking Tiles any shape, pattern, colour (8cm thick) m2

Ceramic wall tiles any shape, patern, colour m2

With labels legible and intact, identifying brand name and contents.

Mortars, additives, and grouts with hall-marks certifying compliance with specified standards.

Samples supplied:

• Waterproofing and anti-fracture membrane

• Latex liquid, one-half litre with manufacturer's data

• Dry set mortar compound, one kilogram

• Dry set tile grout, one kilogram

3)Kerbs & Concrete Barriers are needed in the road barrier system:

Common size and design

Precast Upstand Kerb Type A (35 x 15 cm) m

Precast Upstand Kerb Type C (40 x 20 cm) m

Precast Mountable Kerb Type C (40 x 20 cm) m

Precast Flush Kerb m

Precast concrete barrier including painting (single sided) m

Precast Concrete Barrier including painting(double sided)m

Dwarf retaining Wall m

Spillways (any type)

Road safety guard rail and delineators:

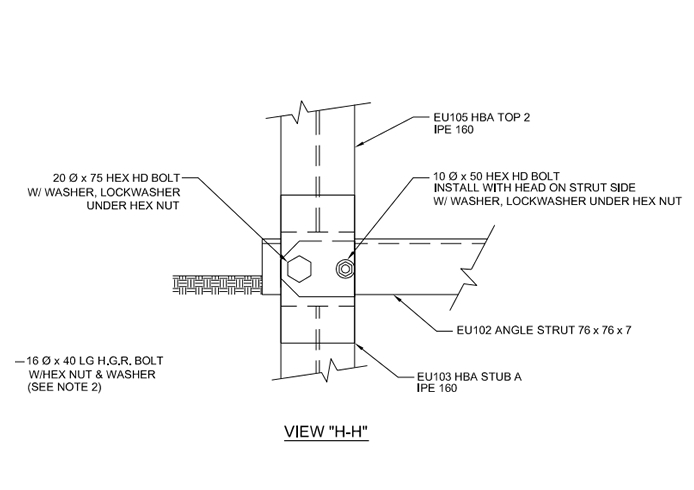

Beams, Posts and Joints

Installing with Hexagon Head Bolt and Washers

Road Safety Guardrail System

Traffic Safety Barriers, PVC Fence

3. SELECtION OF ROAD SAFETY BARRIER SYSTEMS

Considering the performance standard as first priority

Minimum Performance Standard

The minimum performance level for a state highway road safety barrier system is NCHRP 350 Test Level 3 (TL-3). However, in many circumstances, barriers complying with higher test levels will be necessary because factors such as traffic conditions, traffic volume and composition and the cost effectiveness of various safety alternatives must all be considered in the design of road safety barrier systems.

Designers should determine the performance level required for a roadside/median barrier on a case by case basis after due consideration of all factors involved. For example:

(a) The standard roadside protection is a TL-3 barrier but some features, such as a school playground located close to the toe of fill embankment on the outside of a high speed horizontal curve, warrant the provision of a higher performance roadside barrier.

(b) High proportions of heavy and/or dangerous goods vehicles in the traffic stream will usually require TL-4 barriers as a minimum.

(c) Even higher performance barriers, ie. a TL-5 barrier that will contain 36,000 kg truck or a TL-6 barrier that will contain a 36,000 kg tanker, should be used at locations where there are high proportions of heavy

and/or dangerous goods vehicles in the traffic stream, and there would be serious consequences if such a vehicle penetrated, or rolled over, the barrier.

(d) The standard bridge edge protection is a TL-3 barrier but the Transit New Zealand Bridge Manual (Bridge Manual) edge protection criteria will often require the provision of a TL 4 barrier, which will contain an 8,000 kg truck, in most cases.

The Bridge Manual contains a method for determining the appropriate barrier test level for any given situation and it must be complied with when dealing with barriers on bridges. The method is also equally relevant for determining the appropriate test level for roadside and median barriers.

4. TYPES OF ROAD SAFETY BARRIER SYSTEMS

Different types of road safety guard rails are considered for different sites and applications.

Roadside and Median Barriers

3 major types of guard barriers for road safety and median barriers:

(a) Flexible Systems

Flexible barrier systems, e.g. wire rope barriers, are generally more forgiving than other types because most of the impact energy is dissipated by deflection of the barrier and lower impact forces are imposed on the vehicle and its occupants.

All wire rope barriers approved for use on state highways have different deflection characteristics for a given NCHRP 350 test level.

(b) Semi-rigid Systems

Semi-rigid barrier systems, e.g. W-Beam and Thrie-Beam barriers, are the most common type of road safety barrier used in New Zealand. This type of system redirects vehicles mainly by the beam action of the relatively strong steel rails transferring impact loads to closely spaced posts, which in turn transfer the loads to the ground.

Semi-rigid barrier systems have much less lateral deflection than flexible systems.

Examples of semi rigid road safety barrier systems available in New Zealand are:

• Strong Post W-Beam - TL-3

• Strong Post Modified Thrie-Beam - TL-4.

(c) Rigid Systems

Rigid barrier systems, e.g. concrete barriers, work by transferring vehicle impact loads directly into the ground, resisting impacts through the inertial resistance of the barrier mass and its sliding resistance across the ground. The face of these barriers is designed to absorb impact energy by partly lifting the vehicle and controlling the behaviour of the vehicle after impact.

Rigid barriers have no lateral deflection.

Bridge Barriers - Road Safety Barrier for Bridges

Road safety barriers on bridges tend to appear similar in design to roadside barriers, unique in their design for bridges.

Bridge barriers must comply with the requirements of the Bridge Manual.

Guidelines for the retrofitting of guardrails to existing bridges are in preparation.

4.3 Crash Cushions and End Terminals

The end of a barrier is a point of major concern. A crashworthy end treatment, conforming to NCHRP 350 TL-3, must be provided when the end of a barrier is vulnerable to head-on impacts.

4.4 Transitions

A non-rigid barrier should be gradually stiffened on the approach to a connection with a more rigid object such as a bridge barrier, a retaining wall, an abutment wall, or another structural support. The transition design should result in barrier that will permit an impacting vehicle to be smoothly redirected without pocketing or snagging of the barrier.

5.2 Crash Cushions

Various designs of crash cushion including: metal-beam “bullnose” attenuators.

5.3 Aesthetic and Environmental Considerations

While aesthetics are a consideration, they are not normally controlling factors in the selection of a side protection barrier, except in the environmentally sensitive locations such as recreational areas or parks. In such cases, it is important that the systems used be crashworthy as well as visually acceptable to the road controlling authority.

It is also important to consider environmental factors in the selection process.

For example:

• Barriers with considerable frontage area may contribute to a build up of drifting sand or snow in some areas.

• metal railing barriers may deteriorate rapidly in highly corrosive urban/industrial environments.

In some cases, solid barriers may restrict sight distances of drivers entering from a side road or intersection, or may block a driver's view of a particularly scenic panorama.

ROADSIDE BARRIER SYSTEM MAINTENANCE

6.1 Routine maintenance

Routine maintenance costs are similar for all operational roadside barrier systems. Some cleaning and painting is occasionally done, but the use of preservative-treated wood posts and galvanized steel components has nearly eliminated the need for this work. Periodic re-tensioning of cable barrier systems may be required. Graffiti on concrete barriers can present an ongoing maintenance cost. Some systems may interfere more with roadside mowing and vegetation control.

6.2 Collision maintenance

The amount and cost of repairs after an impact by a vehicle can play an important role in the system selection. The number of impacts that are likely to occur along a particular section of barrier depends on a number of factors, primarily traffic speed and volume, road alignment and the distance between the edge of the traffic lane and the face of the barrier. The extent of barrier damage for any specific impact depends upon the strength of the system.

Collision maintenance costs may become an overriding consideration in areas where traffic volumes are extremely high, and barrier impacts are frequent, such as on urban expressways and motorways where barrier repair is difficult to accomplish without interfering with road users. For this reason, rigid concrete barriers (e.g. “F-type” profile), are often preferred at such locations, particularly in median applications.

A further consideration in collision maintenance for post and rail systems is the ability of the rail element and possibly the posts to be re-used after a hit. Savings may be possible if the rail can be straightened. In some cases, of course, the rail will be damaged beyond repair, in which case the salvage/scrap value may be a consideration.

6.3 Material and Storage Requirements

Before selecting a barrier system, the future availability of the repair materials and their storage requirements should be considered. The need for stocking spare parts increases as the number of parts required increases. Thus, there are obvious advantages of using only a few barrier systems whose component parts are standardized, easy to stockpile and readily available.